Project Overview

The factory has 17 die-casting machines controlled by Mitsubishi PLC Q06CPU, and the touch screen is Fuji Monitouch V812iSD. PLC controller makes motion control on die-casting machine, and collects external sensor data then processes. It cooperates with the robot to complete die casting, trimming, stripping operation of auto parts. The touch screen (HMI) can display device status information and it can set PLC parameters at the same time.

Field Research

Field Research

1. No PLC source program

2. Required up to more than 100 data, including DI, AI and etc

3. IP address of PLC are different with the IP network segment of MES

4. The downtime is short

5. The cabinet interior space is narrow

Solutions

Project Summary

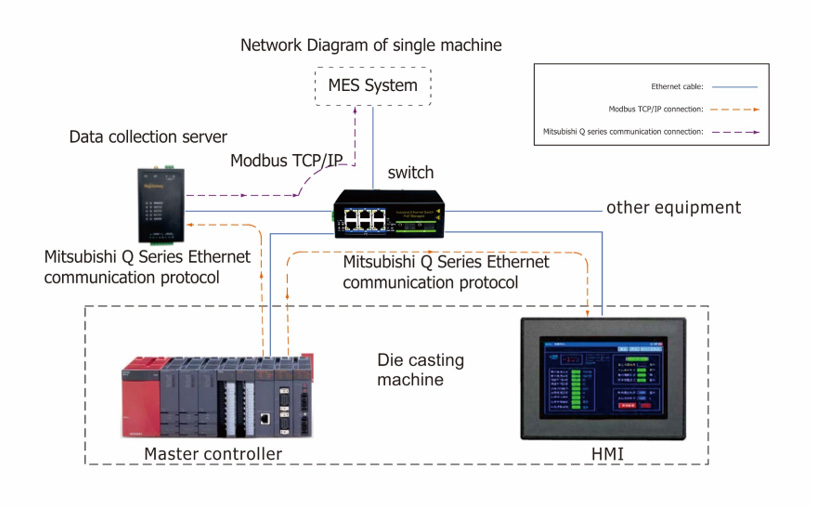

Data acquisition server established connections with main controller via communication protocol, the data was acquired from the main controller, and then through the connection with upper PC whose data it released to, so as to realize the main controller data collection.

According to some scattered data of field instruments, ODOT - MV103 data acquisition server has RS - 232, RS - 485 and Ethernet multiple interfaces support.

MES system via data acquisition server sent data message containing with the IP address, port number, function code, data address, data length and other parameters, so it can obtain the data we need.

Through the connection with our ODOT- MV103 data collection server in Ethernet and the networking of equipment data can be realized.

Post time: Mar-10-2020