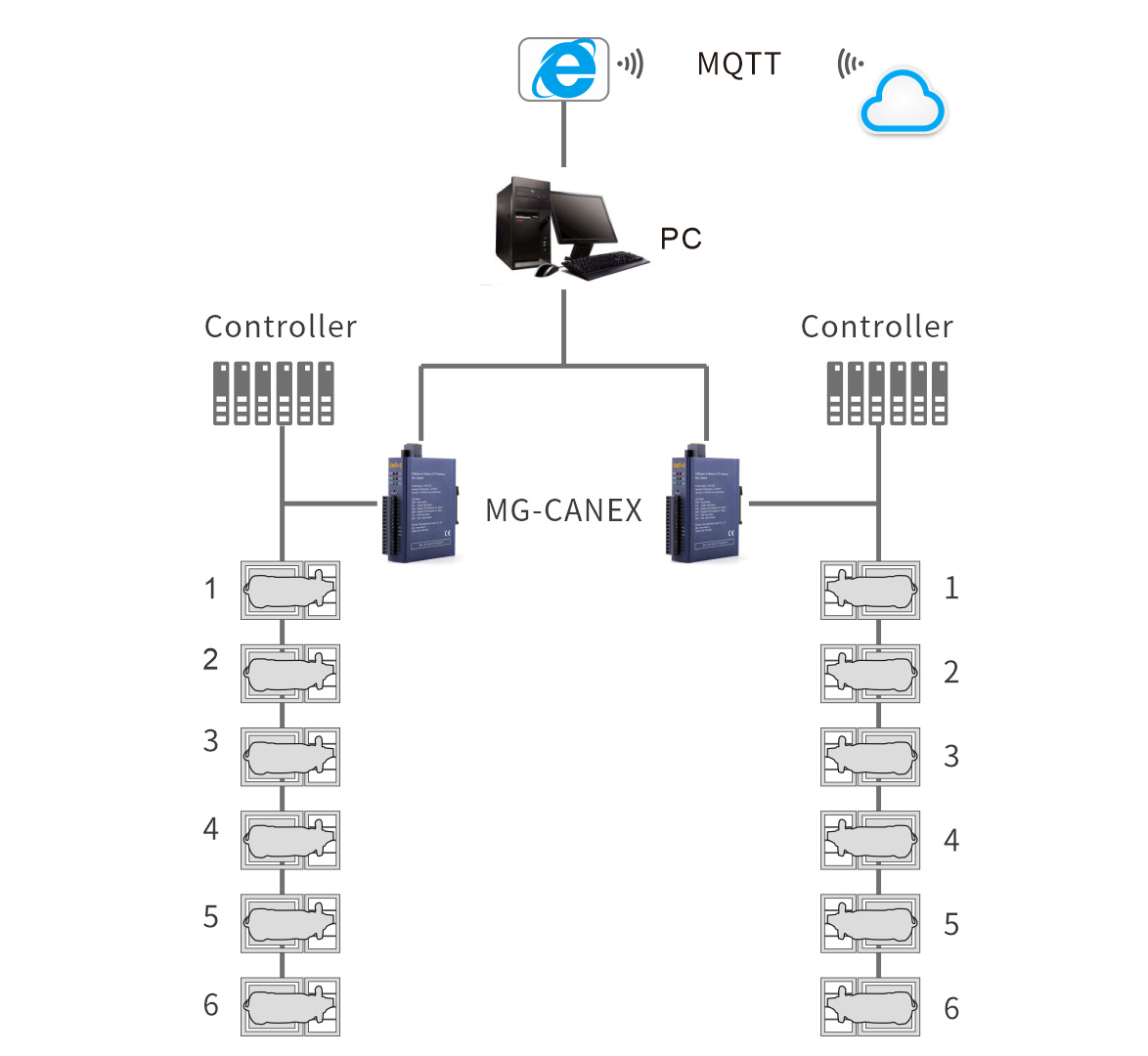

Case and topology

A large livestock breeding company mainly engaged in pig farming. During the entire feeding and management process, many steps are operated automatically. In these steps, the pig feeding is the most important part. Through this management of feeding delivery, a precise pig feeding would be realized, which could effectively eliminate the waste of pig feed while ensuring the growth of pigs.

Field Introduction:

The pig feeding adopted with the feeding equipment from a well-known international company, which had already realized the accurate delivery of the feed, and the equipment was also supported with management software. However, the presented data model was limited, and the basic database could not be collected via the supporting software, and the information needed to be processed again to meet the needs of the customer so it could collect more information for the pig breeding. Therefore, the customer wanted to develop a more powerful and practical management platform beside of the original supporting software. So ODOT Automation System Co., Ltd. would provide a customized solution for the customer.

ODOT products for the solution:

MG-CANEX is a protocol converter from CANopen to Modbus TCP. The device plays as the master in the CANopen network and it could be connected to the standard CANopen slave devices. The data transmission supports PDO, SDO, and error control supports Heartbeat. It Supports synchronous and asynchronous message sending.

As a TCP server in Modbus TCP network, the device could be accessed by 5 TCP clients at the same time, and it could be connected to PLC controller and various kinds of configuration software. It could also connect optical transceiver and to realize long-distance data transmission.

Methods of basic data acquisition for software development

1. Automatic reform, it requires to add sensors to the original equipment to collect basic data;

2. Collecting the original equipment data through a smart gateway.

Comparison of the two methods:

1. The Automatic reform method requires low technical requirements. It could be realized by installing various sensors. However, the hardware cost is high, and the original equipment has to be wired and drilled, also data synchronization of original system and install system could not be guaranteed.

2. Using smart gateway to collect data from the original equipment. This solution requires high technical requirements, high risks, and high initial input cost, but the data would have a strong consistency, and there is no need to add various types of sensors. The on-site implementation cycle is short, and the data is stable and reliable.

After the comprehensive consideration, the customer chose the scheme 2 to collect the basic data of the original equipment.

Project implementation:

After knowing the customer needs, we first confirmed the plan is feasible, and carried on the project according to the following steps:

1. After the customer was agreed, our engineers went to the site of the breeding company to test and analyze the communication methods between the management platform of the feeding equipment and the on-site collection equipment. And we had issued a test report to the customer;

2. According to the analysis of the site situation, and combined with our long-term experience of customized gateways, it was confirmed that the underlying data of the device could be collected;

3. And the data collection plan was confirmed, so at first we started to customize gateway hardware platform and entered the prototype production. Meanwhile, the corresponding software R&D is carried out;

4. After the customized gateway and the software is completed, we simulated an on-site operation platform to test the reliability of the customized gateway;

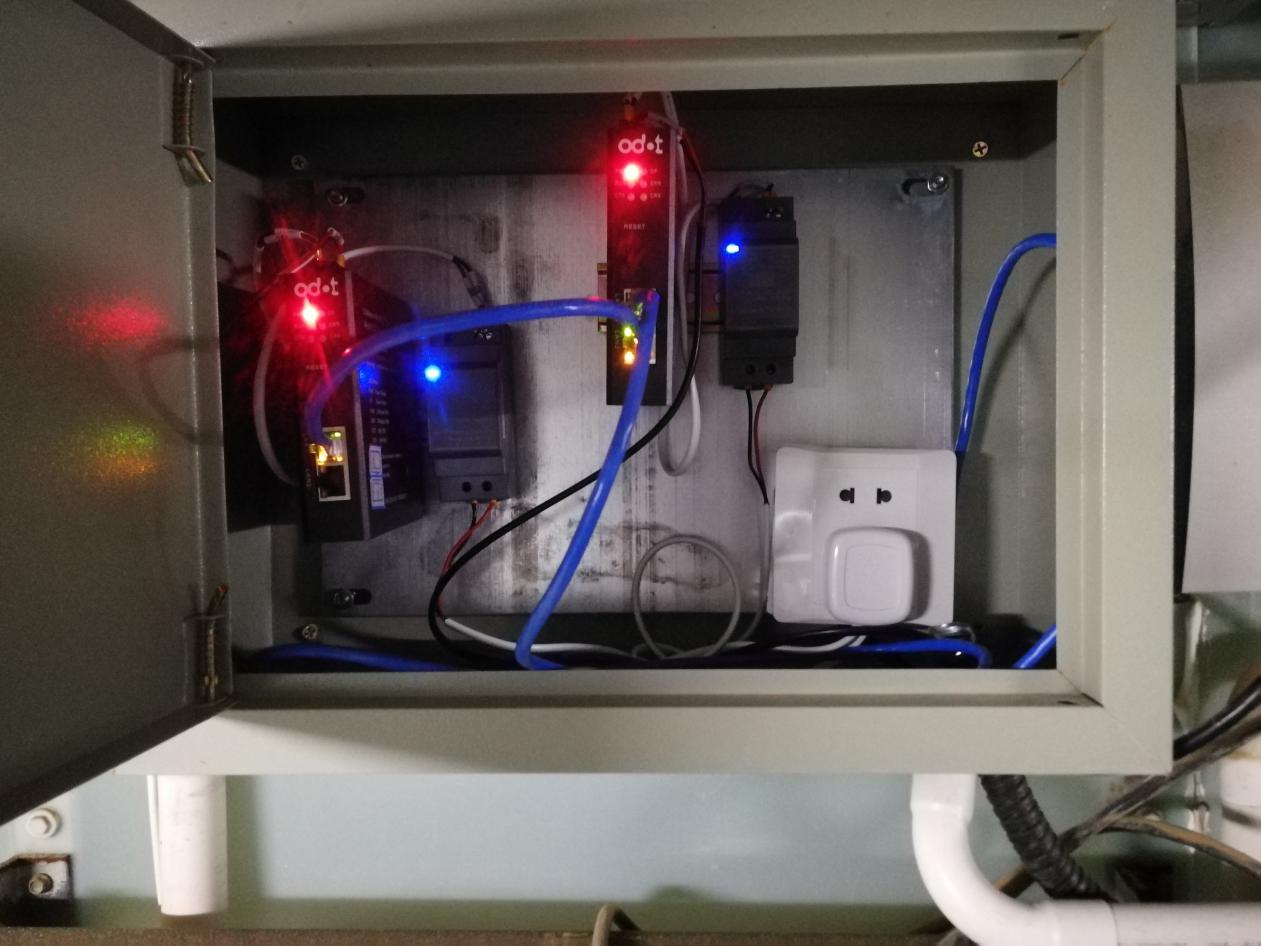

5. After the test ok, the gateway was sent for field testing. According to the feedback from the field test, the customized gateway could be debugged remotely;

6. After the test was done, the gateway kept on running on site for a long time to verify the stability.

Highlights:

The feeding equipment uses a private communication protocol. And with the ODOT R&D center of its software and hardware R&D capabilities, the customized gateway had been successfully developed.

Conclusion:

Our customized CANEX-SY (developed based on MG-CANEX) is operated stably in site. And the data of the feeding device is collected without affecting the normal operation of the original equipment. Also the collected data could be used for the secondary development of the software development company. The data collected by the software company based on CANEX-SY is independent of the data and analysis presented on the original platform to meet the needs of customers.

Post time: Nov-05-2020