Project Overview

Textile is a typical physical processing production technique. The process is the organization and reorganization of structure between fibers. As one of the oldest industries in China, textile plays an important role in the national economy. As so far, China has been a huge textile country in the world, but comparing with international level there is a great gap, such as textile industry automation level and information level. Some factories still use extensive production mode, or even gauged by hand.

Field Research

1. Project location: a chemical fiber enterprise in Zhejiang

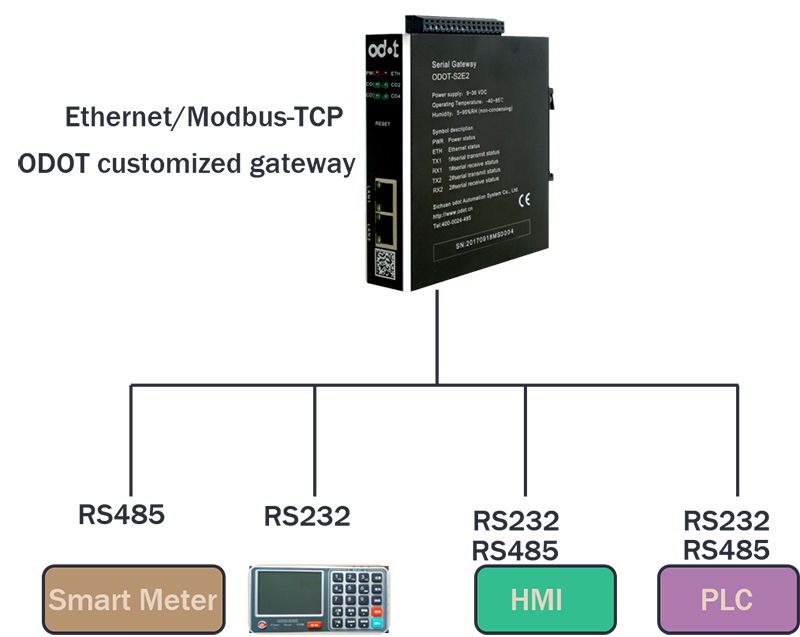

2. Customer requirement: data of 150 sets of textile equipment needs to be acquired in field, and then transmit the data to terminal products provided by MES company through the RS232 port in specified format, and the normal operation of the original production equipment cannot be influenced. Reserves 1 serial port in advance and it can be used to collect data of smart meters and other standard Modbus - RTU equipment. Reserve 2 roads of Ethernet interface so that it could access to the cloud server in the future.

3. Time Requirements: 3 months

Challenge

◆ PLC and HMI both have no extra communication interface

◆ PLC or HMI has extra communication interface, but both have no source program.And PLC or HMI was encrypted and unable to upload the program.

◆ PLC or HMI has available source program but it exists risk for modification and the terminal user may not allow the modification.

◆ PLC or HMI has source program but the programs are encrypted.

Solutions

For the turnkey project, there is no need for our clientele to focus on the underlying equipment manufacturers and other information, instead only need to tell us what data you need. And when the project is near finished we will provide you a point table with unified format for your company to make in-depth use of it. Our product hardware with a 3 - 5 years warranty which are produced in a standardized way and can be updated into different firmware, after updating it can be directly replaced in field, plug and play, without too much setting (the premise is there is no change of PLC and HMI of user). The network topology is simple and the troubleshooting is convenient and fast.

Post time: Nov-28-2020