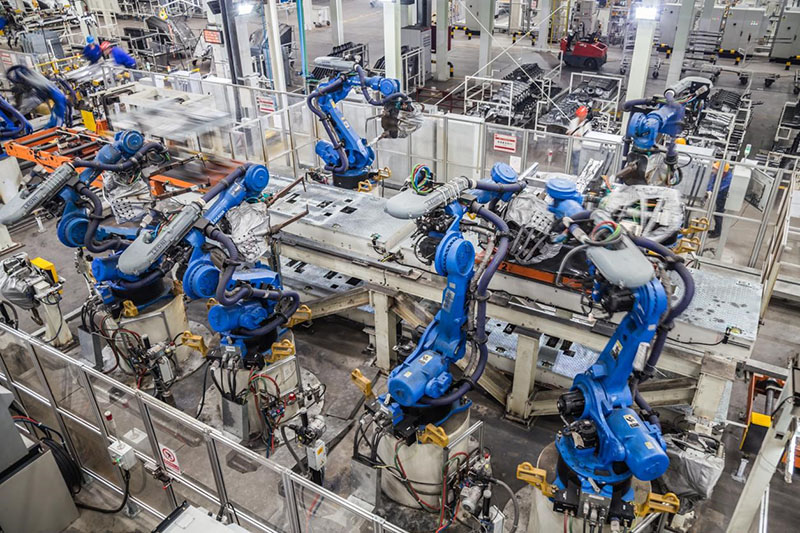

Car seats are crucial components of automotive interiors. The production of car seats involves specialization and complexity. Specific steps include stamping, welding, painting, foam padding, seat assembly, seat testing, and packaging for storage. Currently, specialized factories handle seat production within the industry, providing customized products for vehicle assembly.

Among these processes, welding stands out as particularly significant. Typically, welding robots are employed for high-precision, high-workload welding operations. As a result, the welding process demands greater accuracy in data collection and stability in equipment.

Customer Story

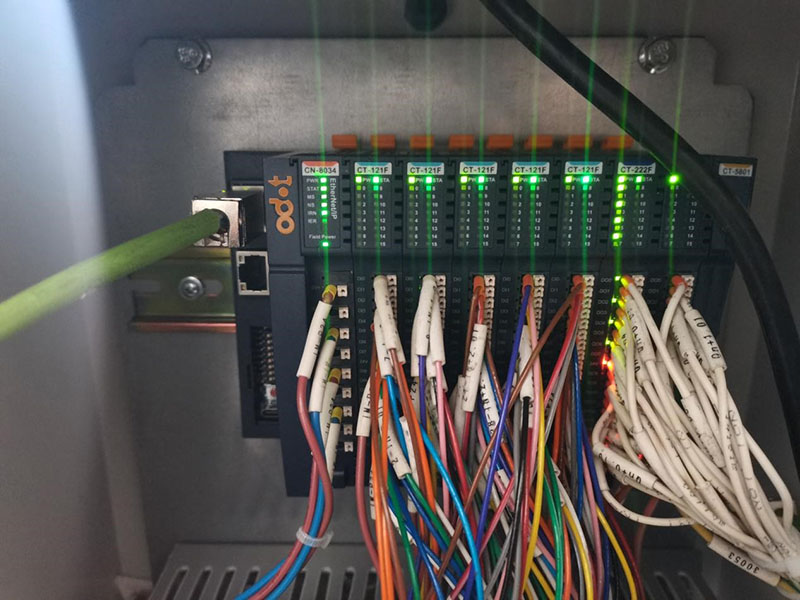

In the welding process, ODOT C-Series Remote IO is trusted by many customers due to its excellent technical parameters and robust product quality. Taking a specific client as an example, in an industrial setting, they utilize the CN-8034 paired with 5 CT-121F modules and 2 CT-222F modules for data acquisition and transmission. The CT-121F digital input module is employed to determine if the fixture’s clamp is in position and for on-site manual operation buttons. Meanwhile, the CT-222F digital output module drives two five-way double-coil solenoid valves to control cylinders.

Product Highlights

The CT-121F module is a 16-channel digital input module that receives high-level signals or connects to PNP-type sensors, accommodating dry contact or active signals. Regarding dry contact signals, due to the presence of an electric arc between contacts at the moment of signal connection, a significant amount of high-frequency noise is generated for a brief period. To address this, the CT-121F module comes with a default factory setting of 10ms per channel, filtering out noise generated within this 10ms window, ensuring accurate data collection. However, for clean active output signals, the filtering time can be manually disabled, allowing for quicker response times. If the filtering time is set to 0, the signal response time can reach as fast as 1 ms.

On-site configuration for button signals and clamp position signals based on these characteristics can significantly enhance system performance.

The CT-222F module is a 16-channel digital output module that outputs 24VDC high-level signals, suitable for driving small relays, solenoid valves, etc., making it ideal for this project site. Additionally, ODOT Automation has designed various models of digital output modules to suit different usage needs, covering a wide range of application scenarios. Apart from conventional models like 8-channel, 16-channel, and 32-channel modules, there are independently powered transistor modules, high-current transistor modules, and modules for DC/AC relays, catering to diverse application scenarios with suitable modules.

ODOT C-Series Remote IO Advantages

1. Supports various communication protocols: Modbus, Profibus-DP, Profinet, EtherCAT, EtherNet/IP, CANopen, CC-Link, and more.

2. Rich variety of expandable IO module types: digital input modules, digital output modules, analog input modules, analog output modules, special modules, hybrid IO modules, etc.

3. Wide temperature design from -35°C to 70°C, meeting stringent industrial environment requirements.

4. Compact design that effectively saves cabinet space.

That’s all for this edition of #ODOTBlog. Looking forward to our next sharing!

Post time: Dec-14-2023