With the continuous development of the socio-economic landscape and the ongoing urbanization, various construction projects are exhibiting an increasingly growing demand for steel. Simultaneously, there is a growing concern from all sectors of society regarding the production quality in the steel industry. This emphasis necessitates steel companies to place greater importance on quality control in production.

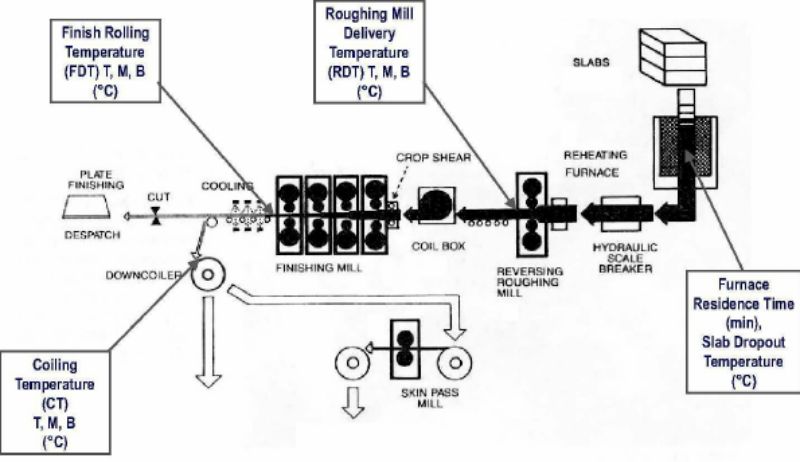

1.Steel Production Process

The steel production process mainly comprises ironmaking, steelmaking, and rolling processes.

As a fundamental industry for the nation’s raw materials, the steel industry’s production quality in the rolling process significantly impacts subsequent stages. Therefore, enhancing the quality during the steel rolling process holds paramount importance. Optimizing production lines through automated equipment enables effective cost control, rational resource utilization, and reduced operational costs for enterprises. This approach better meets the development needs of steel rolling companies.

2.Field Case Study

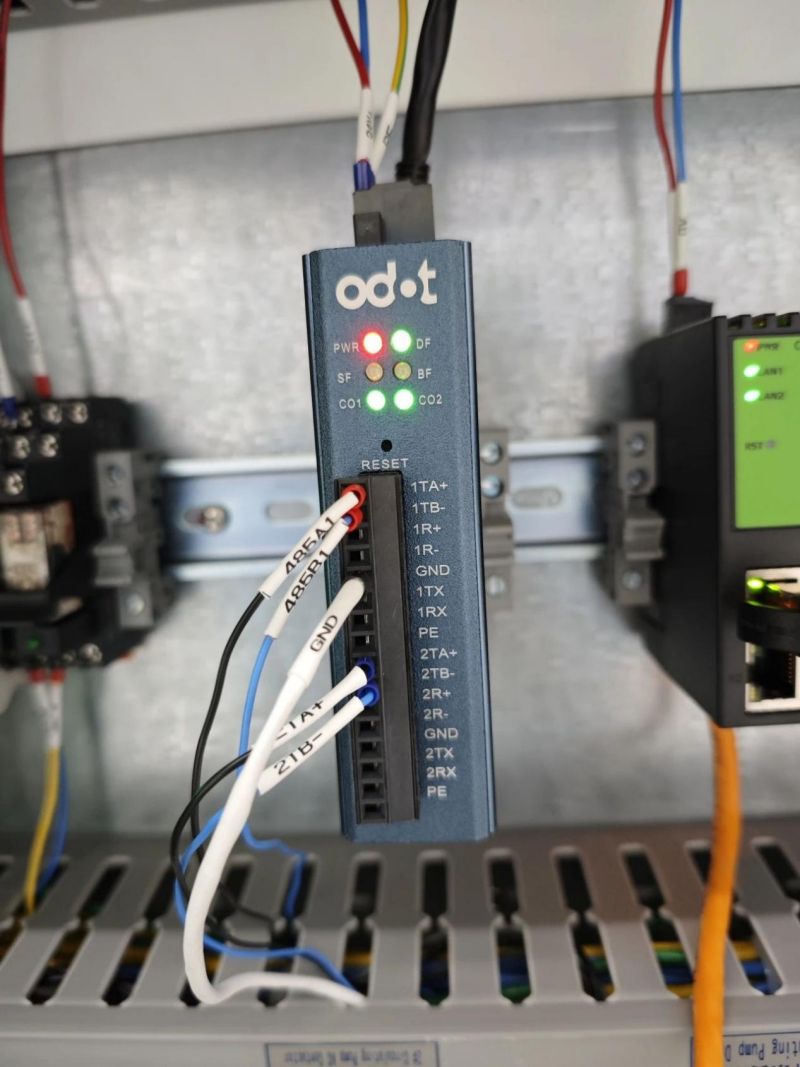

Taking a certain steel plant as an example, some sensors and actuators use the Modbus RTU protocol for communication. In order to enhance data transmission efficiency and real-time monitoring of devices, the steel plant decided to convert the Modbus RTU protocol to Profinet. Technicians from the steel plant communicated with ODOT Automation to inquire whether there were viable solutions available.

Initially, before the project initiation, our technical experts evaluated the sensors and actuators in the steel plant that were using the Modbus RTU protocol. This assessment aimed to gather information on communication parameters, data formats, quantity, types, and distribution of devices. Based on this evaluation, a suitable protocol converter—ODOT-PNM02—was selected.

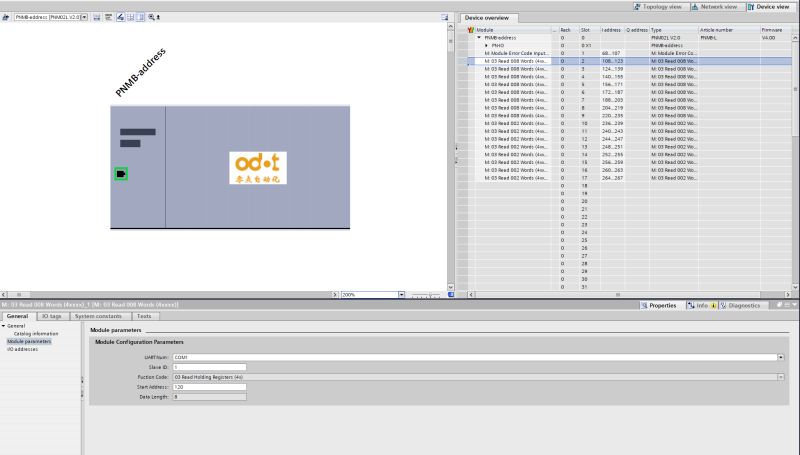

During the project debugging phase, using this protocol converter was remarkably simple and convenient. Engineers no longer needed to write cumbersome communication programs as before. They only had to install the GSD file provided by our company for configuration. By correlating the communication parameters of the Modbus RTU slave devices, and adding corresponding read and write instructions, the Siemens programming software automatically allocated converted data addresses. Engineers could directly reference these allocated addresses within the program, completing the conversion from the Modbus RTU protocol to the Profinet protocol.

3. Product Advantages

This protocol converter has three operating modes: Modbus master mode, Modbus slave mode, and free port transparent transmission mode, which can meet the needs of 95% of customers. It also includes a diagnostic function. When troubleshooting becomes challenging, you can add the “module error code input” command to identify the problem area based on the displayed error code, facilitating a quick resolution.

Upon completion of the project implementation, ODOT Automation also provides comprehensive after-sales service and technical support to ensure the long-term stable operation of the protocol converter.

That’s all for this edition of #ODOTBlog. Looking forward to our next sharing!

Post time: Dec-28-2023