Today, the “dual carbon” target is a familiar new term.The energy saving and emission reduction of enterprises not only benefits the country and the people.

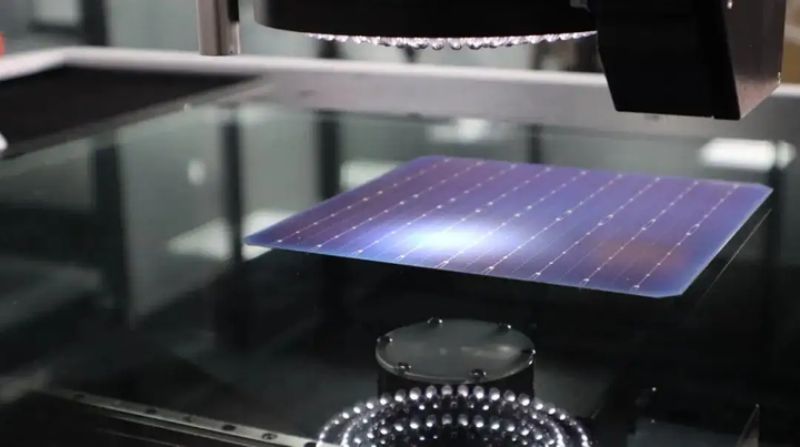

In the background of rapid development in modern industry, solar photovoltaic power generation, as an emerging renewable energy source, effectively alleviates the problem of energy scarcity. The widespread application of electrical automation technology has greatly increased the efficiency of solar panels’ production, playing a positive role in promoting the vigorous growth of the photovoltaic industry.

The principle of texturing in photovoltaic silicon wafer manufacturing

Texturing in photovoltaic solar cell manufacturing is a process that involves surface treatment of solar cells to enhance their photoelectric conversion efficiency. The primary principle behind texturing in photovoltaic solar cell manufacturing is the creation of a fine texture structure on the surface of the solar cell. This structure increases light scattering and absorption, thus improving the photoelectric conversion efficiency.

Texturing enables light to undergo multiple reflections on the surface of the solar cell, enhancing the interaction between light and the solar cell. This, in turn, increases the solar cell’s ability to absorb light.

Industry challenges

Texturing machine equipment length is relatively long, and if the traditional approach of using PLC expansion modules is adopted, it significantly increases wiring costs and construction complexity. When faults occur, troubleshooting becomes difficult, which can impact production schedules.

Photovoltaic texturing machines have multiple input and output points, including signals for sensors indicating position and temperature measurements, as well as output signals controlling the actions of driving relays and solenoid valves, among other related devices. Using traditional PLC expansion modules significantly increases module costs and occupies a substantial amount of cabinet space during installation, making wiring a challenging task.

The application of ODOT IO in photovoltaic silicon wafer texturing machines

XX Machinery Co., Ltd. is the leading company of solar industry in China, and their control system utilizes a Siemens 1500 PLC. for expanding the input and output points, they have chosen Sichuan ODOT Automation CN-8032-L Profinet distributed remote IO modules.

Input signals include indicators for the mechanical arm reaching its upper position, the mechanical arm reaching its lower position, the mechanical arm moving to the left position, the mechanical arm moving to the right position, temperature measurements of the probing needle, chemical liquid levels, total flow rates, and instantaneous flow rates, among others. Output signals encompass signals for dosing solenoid valve switching, circulation pump switching, chemical liquid heater switching, inverter start/stop signals, and more.

The photovoltaic silicon wafer texturing machine has a total of over 800 input and output points. They have opted for 10 CN-8032-L Profinet network adapters combined with IO modules for distributed control. This setup fulfills all on-site input and output control requirements while reducing wiring costs and module procurement costs. The installation of the C-series distributed remote IO modules is convenient, and in case of on-site issues, troubleshooting is easy, ensuring production stability and efficiency, ultimately helping customers reduce costs and increase efficiency.

ODOT C series IO features

1. Support a variety of communication protocols: Modbus, Profibus-DP, Profinet, EtherCAT, EtherNet/IP, CANopen, CC-Link and so on.

2. Extended IO modules: digital input module, digital output module, analogue input module, analogue output module, special module, hybrid IO module, etc.

3. -40℃-85℃ wide temperature design tomeet the extreme industrial environment.

4.Compact design, effectively saving space inside the cabinet.

In the solar industry, the widespread application of electrical automation not only effectively improves system efficiency but also reduces the human workload to a certain extent. Moreover, it ensures the stability and safety of the electrical system, thereby driving the overall development of the power industry.

On the path of future development, ODOT will not forget our initial purpose, remain committed to customer-oriented approaches, and continuously advance industrial automation and the development of the new energy industry. This dedication aims to support the nation’s efforts to achieve the “dual carbon” strategy for new energy .

Post time: Nov-09-2023